When it comes to upgrading your wheels, not all options are created equal. The choice between cast and forged wheels isn’t just a matter of looks; it affects your vehicle’s performance, strength, weight, and long-term value.

Understanding how each type is made, and what that means on the road, can be the difference between a wheel that delivers lightweight, high-performance durability and one that may crack under pressure. Whether you’re building a show car or pushing your ride to the limit, knowing the facts matters.

In this guide, we’ll break it all down with clear comparisons, real-world use cases, and insights into which option is best for your vehicle. No jargon, just straight answers. And when you’re ready to upgrade, AudioCityUSA is here with the brands and expertise to get you rolling right.

Discover the Real Difference Between Cast and Forged Wheels

When you’re choosing between cast and forged wheels, you’re not just picking a design you’re deciding how your wheels will perform, how long they’ll last, and how much they’ll cost. To make the right choice, it’s important to understand how each type is made and what that means for your vehicle on the road.

Manufacturing Process: Where It All Begins

Cast Wheels are made by pouring molten aluminum into a mold, then cooling it into a one-piece wheel. This process is relatively simple and cost-effective, making it possible to produce visually complex designs at scale. It’s a solid option for drivers looking for affordability and style.

Forged Wheels, on the other hand, are crafted from a solid billet of aluminum that’s pressed under thousands of tons of pressure before being precision-machined into its final shape. This high-pressure forging process compresses the grain structure of the metal, resulting in a wheel that’s denser, stronger, and more structurally uniform.

Weight: Lighter Isn’t Just Better It’s Smarter

Forged wheels can be up to 25–30% lighter than cast wheels of similar size and design, offering a substantial reduction in unsprung weight for performance applications. Because of their superior strength, they require less material, which results in slimmer designs and reduced unsprung weight, leading to sharper handling, quicker acceleration, and improved braking.

Cast wheels, while durable for everyday use, are heavier due to the need for more material to compensate for internal porosity from the casting process. This added weight can slightly dull your car’s responsiveness, especially in high-performance applications.

Strength & Durability: Built to Take the Hit

A well-made forged wheel is exceptionally strong. Due to their dense grain structure, forged wheels typically offer better impact resistance and are more likely to bend rather than crack, whereas cast wheels are more brittle and prone to cracking under sudden or severe force.

Cast wheels, though more than sufficiently strong for daily use, can be brittle by nature and may crack under extremely heavy loads or severe impacts, such as potholes or track use. They’re reliable for standard driving conditions, but not built for high-stress performance.

Cost: Upfront Price vs. Long-Term Value

Casting is a faster and more affordable manufacturing method, which keeps costs low. It’s ideal if you’re customizing on a budget or replacing stock wheels. They typically will provide the same visual impact and design variety you can expect from forged and flow-formed wheels, but aren’t normally designed for the rigorous demands of off-road terrains or race-tracks.

Forged wheels come with a higher price tag, due to the labor-intensive process and advanced engineering involved. However, they often pay off in the long run with better performance, longer lifespan, and improved safety under demanding conditions.

Use Cases: Which One Fits Your Drive?

Cast wheels are the go-to for daily drivers, show builds, and budget-conscious upgrades. They’re ideal if your priority is practicality or style and not necessarily shaving seconds off lap times.

Forged wheels are built for those who expect more. Whether you’re into track days, spirited weekend drives, or own a high-performance or luxury vehicle, forged wheels offer the lightweight strength and durability needed to perform under pressure.

Exploring Your Options: Cast vs. Forged Wheels in Detail

Now that you understand the key differences between cast and forged wheels, it’s time to take a closer look at what each option really offers. Whether you’re upgrading for performance, aesthetics, or everyday reliability, knowing the unique strengths and trade-offs of each type will help you make the right choice for your vehicle and driving style.

Let’s start with cast wheels, an accessible and stylish option trusted by drivers around the world.

Cast Wheels: Affordable, Stylish, and Perfect for Everyday Rides

If you’re looking for a wheel upgrade that delivers both style and value, cast wheels are one of the most accessible and widely used options on the market. Favored by everyday drivers and custom builders alike, cast wheels offer an impressive balance of cost, design flexibility, and availability, making them a smart choice for many street vehicles and show builds.

How Cast Wheels Are Made

Cast wheels are manufactured using a relatively simple yet effective process. Aluminum alloy is melted down and poured into a mold, then cooled and solidified into the shape of a wheel. Once cooled, the wheel is machined for precision trimming edges, drilling bolt holes, and applying surface finishes. This method allows for mass production, creative designs, and one-piece constructions, all at a lower cost compared to other manufacturing techniques.

Why Cast Wheels Make Sense

There are plenty of reasons why cast wheels are the go-to choice for many drivers. Here’s what makes them stand out:

● Budget-Friendly: Cast wheels are generally more affordable than forged or flow-formed alternatives. You get great aesthetics and functional performance without a premium price tag.

● Design Variety: Casting allows manufacturers to offer a wide range of styles, sizes, and finishes from timeless multi-spoke designs to aggressive concave looks. There’s a cast wheel to suit nearly every taste and build.

● Availability: Since most OEM wheels and many aftermarket options are cast, finding replacements or upgrades is straightforward. There’s no long lead time, and availability is widespread.

● Daily Use Ready: For city driving, commuting, weekend cruising, or even show builds, cast wheels offer more than enough durability and visual impact. They’re ideal for enthusiasts who want to upgrade their look without diving into track-level performance needs.

Things to Consider

As with any wheel type, cast wheels come with a few trade-offs:

● Heavier Weight: Due to the presence of microscopic air pockets formed during the casting process, manufacturers often need to use more material to maintain strength. This can result in a heavier wheel, which slightly impacts acceleration and responsiveness.

● Lower Ultimate Strength: Cast aluminum is more brittle than forged, meaning it can crack under high stress or hard impacts like hitting a deep pothole at speed or aggressive cornering with high-grip tires. It’s less suited for high-performance or heavy-duty applications.

● Porosity Issues: While porosity is common in cast wheels, reputable brands minimize this risk through strict quality control. Poorly cast wheels may experience reduced fatigue strength over time.

Where Cast Wheels Shine

Cast wheels are an excellent fit for a range of applications where cost, design, and everyday durability matter most:

● Street Cars & Custom Builds: Perfect for daily drivers and car enthusiasts looking to enhance their vehicle’s style without sacrificing practicality. Many top aftermarket options from brands like Fuel Off-Road and Niche Road Wheels are cast.

● Budget-Friendly Upgrades: For drivers who want an upgrade in style without a premium price tag, cast wheels offer exceptional value.

● Visual Impact: Available in larger diameters (20”+), cast wheels are a go-to for those who want to give their vehicle a more aggressive stance or refined custom look.

Quality Cast Wheel Brands

Top brands like Fuel Off-Road and Niche have built strong reputations around their one-piece cast wheels. Fuel’s designs are especially popular for trucks and SUVs, offering a balance of strength, style, and off-road credibility. Meanwhile, Niche delivers stylish cast wheels for sedans, coupes, and sports cars, often blending lightweight construction (by cast standards) with head-turning finishes, all available through AudioCityUSA.

Forged Wheels: Unmatched Performance and Strength for Serious Enthusiasts

For drivers who demand the very best in strength, precision, and performance, forged wheels are in a class of their own.

Built to endure extreme conditions and engineered for top-tier handling, forged wheels offer the highest performance gains available in the aftermarket wheel world.

While they come at a premium, the benefits are undeniable, especially for those who push their vehicles to the limit.

How Forged Wheels Are Made

Forged wheels begin with a solid billet of premium aluminum, often 6061-T6, that’s super-heated and pressed under immense pressure, sometimes over 10,000 tons, to form a dense wheel blank. This process refines the internal grain structure of the metal, eliminating air pockets and aligning the grain for maximum structural integrity.

Once the forging process is complete, the wheel is CNC machined to its final shape and specifications, achieving precise fitment, finish, and detail. Forged wheels are available as one-piece monoblock designs or multi-piece constructions that allow for custom widths, finishes, and configurations.

The result is a wheel that is incredibly strong and significantly lighter than cast or flow-formed alternatives.

Why Forged Wheels Lead the Pack

What sets forged wheels apart isn’t just their build quality; it’s what that quality translates to on the road and the track.

● Lightweight Performance: Forged wheels can use 30% less material compared to cast wheels of similar size and design while maintaining strength, making them lighter than cast wheels. Less unsprung weight leads to better suspension response, improved braking, and noticeably quicker acceleration. For anyone focused on driving dynamics, that weight savings is a game-changer.

● Unmatched Strength: Forged wheels are among the strongest aluminum wheels you can buy. Their refined structure makes them far more resistant to impacts and stress fractures.

● Built to Last: Forged wheels are known for their durability and longevity. Many professional motorsports teams use the same forged sets season after season, thanks to their ability to withstand high-stress environments without fatigue failure.

● Real Performance Gains: The combination of lower weight and increased strength means better performance across the board, quicker acceleration, shorter stopping distances, and tighter cornering grip. For performance-minded drivers, forged wheels deliver where it counts.

● Fully Customizable: One of the biggest draws of forged wheels is their made-to-order flexibility. Whether you’re after custom diameters, unique offsets, or a bold color finish, forged wheels can be tailored to fit your exact specifications and style vision.

Considerations Before You Buy

While forged wheels offer top-tier performance, they’re not without trade-offs:

● Premium Price Point: Forged wheels come with a higher cost due to the complexity of their manufacturing process. They’re an investment, but one that pays off in strength, safety, and longevity.

● Longer Lead Times: Because many forged wheels are custom-built, expect longer wait times for production and delivery.

● Not Always Necessary: If your car is mainly used for daily commuting or casual driving, the added benefits of forged wheels may not be fully utilized.

● Limited Smaller Sizes: Forged wheels are more commonly available in larger diameters (18″+). Drivers with smaller vehicles may find fewer forged options without stepping up in size.

Where Forged Wheels Excel

Forged wheels aren’t for everyone, but for serious enthusiasts, they’re often the only choice.

● High-Performance Cars: If you drive a sports car, supercar, or track-ready machine, forged wheels help unlock your car’s full potential.

● Track and Motorsports: Competitive racing demands the safety, strength, and weight savings that only forged wheels can offer.

● Off-Road & Heavy-Duty Builds: Forged wheels designed for off-road use, especially from brands like American Force, offer exceptional load capacity and durability on rough terrain. Not all forged wheels are suitable for off-road applications, especially those optimized for street performance.

● Show Cars with Big Wheels: For custom builds requiring large diameters (24”+), forged multi-piece wheels are often the only safe and stylish option.

Quality Forged Wheel Brands

Top-tier manufacturers like HRE, Forgiato, and American Force lead the forged wheel market with exceptional design and engineering. From track-ready performance to luxury styling and rugged off-road capability, these brands deliver uncompromising quality.

At AudioCityUSA, we proudly carry a full range of forged wheels, including custom options from HRE and Forgiato, giving you access to the best wheels in the industry.

Flow-Formed Wheels: The Best of Both Worlds, Light, Strong, and Budget-Friendly

If you’re torn between the affordability of cast wheels and the performance benefits of forged, flow-formed wheels might be the perfect solution.

Known as the hybrid option in the wheel world, flow-formed wheels offer the ideal balance of strength, weight savings, and value, making them an increasingly popular choice for drivers who want more performance without the premium price of fully forged wheels.

What Are Flow-Formed Wheels?

Flow-forming is a unique manufacturing process that begins similarly to a cast wheel but incorporates a critical final step that enhances strength. After casting the wheel’s center, the barrel is heated and stretched under pressure, a technique inspired by forging.

The result is a wheel that retains a cast center but features a flow-formed barrel that’s significantly stronger and lighter than a standard cast wheel.

This process creates a more dense, uniform grain structure in the barrel, improving the wheel’s structural integrity while keeping production costs lower than full forging.

Why Flow-Formed Wheels Are Gaining Ground

Flow-formed wheels are quickly becoming the go-to for enthusiasts who want real performance benefits without stretching their budget.

● Reduced Weight (Compared to Cast): Flow-forming reduces the overall weight of the wheel by 15–25% compared to a standard cast wheel. That means better acceleration, braking, and handling, especially for performance-oriented builds.

● Improved Strength: While not quite at the level of forged wheels, flow-formed barrels are significantly stronger than standard cast barrels. This added strength increases impact resistance and load capacity, making them suitable for spirited driving and weekend track use.

● Cost-Effective Performance: One of the biggest selling points of flow-formed wheels is their value. They deliver much of the performance advantage of forged wheels, but at a price point that’s closer to cast. For many drivers, they’re the sweet spot between affordability and function.

● Wider Selection and Availability: As their popularity grows, more brands are offering flow-formed options across a range of sizes and finishes, making it easier than ever to find a set that suits your vehicle and style.

Things to Consider

While flow-formed wheels offer plenty of benefits, they’re not without limitations:

● Still Partly Cast: The center of the wheel is still made using a casting process, meaning it’s not as structurally refined as a fully forged wheel. While stronger than a standard cast wheel overall, it is not as robust as a fully forged counterpart.

● Not the Lightest Option: Though they’re lighter than cast, flow-formed wheels don’t quite match the ultra-lightweight advantage of forged wheels, something to consider if you’re building a track-focused vehicle where every pound counts.

● Mid-Range Price: Flow-formed wheels often strike a mid-range price point, more expensive than cast, but generally more affordable than most forged options. However, high-end flow-formed brands can approach forged-tier pricing. If budget is a top priority, cast may still be your go-to, but for those who want added performance without going all-in, flow-form can be a smart upgrade.

Where Flow-Formed Wheels Fit Best

Flow-formed wheels are an excellent fit for a wide range of applications, especially where weight reduction and enhanced strength are desirable, but cost is still a factor.

● Affordable Performance: Ideal for enthusiasts who want better driving dynamics without the cost of forged wheels. Perfect for street builds, spirited weekend driving, or occasional track days.

● Performance Vehicles & Street Racing: Great for cars that see both street and light competition use, flow-formed wheels provide improved handling and responsiveness.

● Better Than Cast: For drivers looking to step up from cast wheels without jumping to the cost of forged, flow-form offers a significant upgrade in strength and weight savings, making them a compelling mid-tier option.

Quality Flow-Formed in Action

Brands like TSW with their Rotary Forged lineup and Stance Wheels’ SF series are excellent examples of flow-forming done right. These wheels are designed for performance, style, and affordability, and are a top choice for sports cars, performance sedans, and even custom street builds.

You can explore these and other flow-formed options through AudioCityUSA, where style meets real-world performance.

Next up, we’ll help you bring it all together, so you can confidently choose the perfect alloy wheels for your vehicle, style, and driving needs. Whether you’re chasing performance, making a style statement, or looking for the best balance of both, you’ll know exactly where to start.

Choosing the Right Wheel for Your Ride: Cast, Forged, or Flow-Formed?

Now that you know the ins and outs of cast, forged, and flow-formed wheels, it’s time to figure out which type is the best fit for your vehicle, your budget, and your driving style. Choosing the right wheel isn’t just about specs, it’s about matching performance, durability, and aesthetics with how you actually use your car.

Start with Your Driving Style

Your driving habits should be the first thing you consider. Be honest, how and where do you spend most of your time behind the wheel?

If you’re a daily commuter, weekend cruiser, or show car builder, cast wheels are a great fit. They provide more than enough strength for everyday use, look great, and won’t strain your budget.

If you regularly hit the track, push your car on rough terrain, or drive aggressively, forged wheels are worth the investment. The strength and weight savings are exactly what performance and off-road applications demand.

If you fall somewhere in the middle, maybe you enjoy spirited driving but don’t push your car to the edge, flow-formed wheels offer the best of both worlds. They provide a noticeable performance boost over cast, without the premium price tag of forged.

Set a Budget That Matches Your Priorities

Understanding your budget and priorities will help you narrow down your choices quickly.

Forged wheels are at the top of the price spectrum, but they deliver unmatched strength, weight savings, and often custom options. If you’re building a performance car or want something completely one-of-a-kind, they’re worth every penny.

If you’re working within a tighter budget, cast wheels often offer nearly identical aesthetic appeal to forged wheels, making them a wise choice for drivers who prioritize styling over performance.

Flow-formed wheels hit the sweet spot for many enthusiasts. They cost a bit more than cast but offer significant gains in strength and weight reduction, making them one of the best bang-for-buck options available.

Consider Your Vehicle Type and Weight

The kind of vehicle you drive plays a big role in choosing the right wheels.

Heavier vehicles, like trucks, SUVs, or luxury sedans, put more stress on wheels, especially over potholes or rough roads. In these cases, a forged wheel’s extra strength can help prevent bending or cracking.

For smaller, lightweight cars, even high-quality cast or flow-formed wheels often provide all the strength and performance you’ll need without over-investing.

Think About Size and Style Goals

Planning to run larger diameters or wider setups? Forged wheels are often the most reliable choice for extreme fitments, especially when pushing the limits of width or lip depth.

However, if you’re sticking to more common sizes, like 17″ to 20″ for cars, or 20″ to 22″ for trucks, you’ll have solid options across cast, flow-formed, and forged wheels.

Choose a design you love from a reputable brand, and there’s a good chance you’ll find a cast or flow-formed version that fits your vision and budget.

Customization Options

If you’re after something truly unique, forged wheels offer the most flexibility. You can often request custom finishes, widths, offsets, or even engraved details that make your wheels truly one of a kind.

Whether it’s a brushed gold finish or a track-ready matte black, forged wheels let you dial in every detail.

Consider the Long Game

If you plan to keep your car long-term and use it hard, think track days, road trips, or hauling, forged wheels offer longevity and resilience that could save you in the long run.

And don’t forget: you don’t have to commit to just one setup. Many enthusiasts run cast wheels for daily driving and swap in forged wheels for track days or special occasions. If you’ve got the space and flexibility, it’s a great way to get the best of both worlds.

Still Unsure? Get Expert Help

If you’re still on the fence about which wheel type is right for you, don’t guess, ask an expert. The team at AudioCityUSA is here to help you navigate your options and find the perfect match for your car, your goals, and your budget.

With decades of experience and a wide range of brands in stock, we’ll make sure you roll out with confidence.

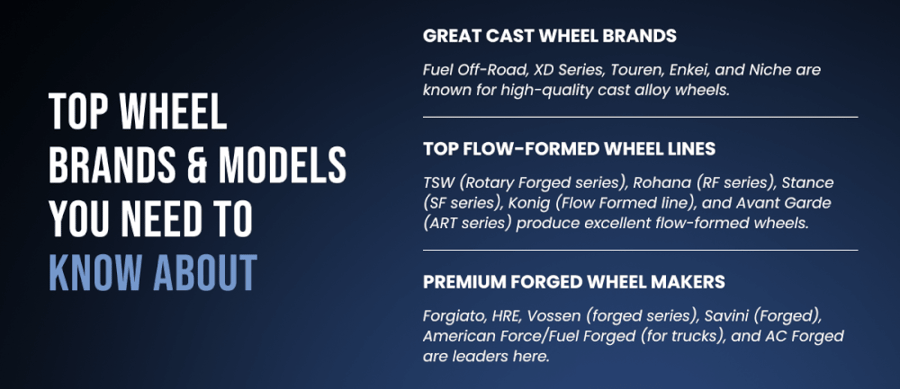

Top Wheel Brands & Models You Need to Know About

● Great Cast Wheel Brands: Fuel Off-Road, XD Series, Touren, Lexani, Giovanna, and Niche are known for high-quality cast alloy wheels.

● Top Flow-Formed Wheel Lines: TSW (Rotary Forged series), Rohana (RF series), Stance (SF series), Vertini, and Avant Garde (ART series) produce excellent flow-formed wheels.

● Premium Forged Wheel Makers: Forgiato, HRE, Vossen (forged series), Savini (Forged), American Force/Fuel Forged (for trucks), and AC Forged are leaders here.

Ready to Upgrade? Find the Perfect Wheels for Your Ride

Now that you know the differences between cast, forged, and flow-formed wheels, and how to choose what’s right for your driving style, budget, and build, it’s time to take the next step.

At AudioCityUSA, we offer one of the most comprehensive selections of alloy wheels in the industry. Whether you’re going for aggressive performance, daily drivability, or custom show-stopping style, you’ll find the right fit in our lineup of cast, flow-formed, and forged wheels, available in a range of designs, finishes, and sizes.

Not sure where to start? Our team of wheel experts is here to help with everything from fitment questions to tire packages, offsets, and customization advice. With decades of experience and a deep understanding of performance and aesthetics, we’ll make sure you choose the right wheels the first time.

When you shop with AudioCityUSA, you’re not just buying wheels, you’re investing in your vehicle’s style, performance, and presence on the road.

Browse our collection today and get ready to drive away with confidence. The perfect wheels are waiting.